In fashion, bottoms are the foundation of every outfit. For brands, custom bottoms1 offer a unique edge in a highly competitive market. But knowing where to start—and what to avoid—can make all the difference.

Custom bottoms allow brands to design original fits, fabrics, and finishes that align perfectly with their identity. From joggers to trousers, they offer the flexibility to meet market trends and customer expectations.

When I first introduced custom flare pants to a streetwear client, they doubted it would catch on. Today, it’s their No.1 selling item. When you control the design, you control the demand.

What Are Custom Bottoms and Why Are They in High Demand?

Custom bottoms are more than just another product—they’re your brand’s statement.

Custom bottoms refer to uniquely designed pants, skirts, or shorts created to match a brand’s aesthetic, fit preferences, and style goals. This includes joggers, tailored trousers, and street-style silhouettes.

Why the Spike in Demand?

-

Consumer Desire for Exclusivity

People want styles they can’t find at every fast fashion store. Custom bottoms fill that gap. -

Brand-Specific Identity

Bottoms often define the vibe of a look. A well-cut pant or on-trend skirt becomes instantly recognizable and shareable. -

Streetwear & Niche Growth

Streetwear, genderless fashion, and K-style trends are driving interest in joggers, cargos, and flared cuts.

Which Types of Bottoms Can Be Customized for Fashion Brands?

From the runway to TikTok, variety is in demand.

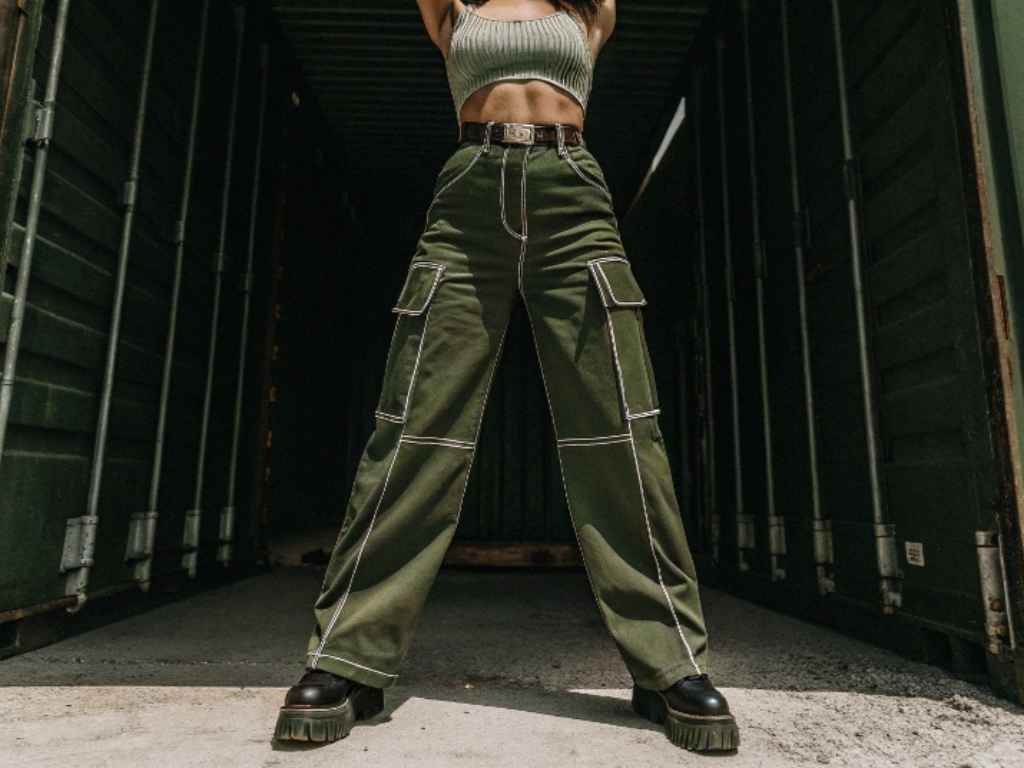

Popular customizable bottom categories include joggers, sweatpants, trousers, skirts, shorts, leggings, flare pants, and co-ord sets. 2024 trends lean toward wide-leg fits, utility cargo features, and Y2K-inspired cuts.

Trending Fits and Bestsellers

| Category | Style Highlights | Best For |

|---|---|---|

| Joggers | Elastic cuffs, fleece-lined | Athleisure, Gen Z casual |

| Trousers | Tailored, high-waist, pleats | Officewear, upscale casual |

| Skirts | Denim minis, ribbed midis | Women’s wear, influencer edits |

| Shorts | Biker, cargo, lounge | Summer drops, co-ord sets |

| Leggings | Crossover waist, contour seams | Fitness brands, maternity lines |

| Flare Pants | Ribbed, velvet, Y2K inspired | Streetwear, unisex styling |

Unisex silhouettes and couple-style sets are also gaining ground, especially in DTC collections.

How Do You Choose the Right Fabric for Custom Bottoms?

Fabric decides how your bottoms wear, breathe, and move.

Choose fabrics based on stretch, weight, season, drape, and dye compatibility. Top choices include cotton, French terry, denim, twill, polyester, linen, and spandex blends.

Fabric Comparison for Bottoms

| Fabric | Stretch | Weight | Seasonality | Best Uses |

|---|---|---|---|---|

| Cotton Twill | Low | Medium | All-seasons | Trousers, utility shorts |

| French Terry | Medium | Light | Spring/Fall | Joggers, sweatpants |

| Denim | Low | Heavy | All-year | Skirts, shorts, wide-leg pants |

| Polyester Mix | Medium | Light | Summer | Sportswear, cost-efficient items |

| Linen | None | Light | Summer | Casual trousers, breezy skirts |

| Spandex Blends | High | Light | Year-round | Leggings, body-hugging fits |

Eco-conscious options like organic cotton, recycled polyester, and bamboo blends are also gaining favor in the custom manufacturing world.

Do Custom Bottoms Help Brands Stand Out in a Crowded Market?

The short answer? Absolutely.

Custom bottoms allow your brand to offer something fresh, exclusive, and true to your visual identity—setting you apart from mass-market competitors.

Details That Make All the Difference

- Branded Finishes: Think custom tags, logo embroidery, and branded drawstrings.

- Design Differentiators: Zipper placements, asymmetrical cuts, contrast stitching, and cargo pockets.

- Social Media Gold: Unique designs perform better on platforms like Instagram and TikTok—leading to higher engagement and organic reach.

Is It Possible to Produce Custom Bottoms with Low MOQ?

Many brands assume high cost and high quantity. That’s outdated thinking.

Yes, small-batch production is possible—even for bottoms. Modern OEM/ODM models allow production runs as low as 100–200 pieces with full customization.

Keeping Costs Down

- Consolidate Fabrics: Use one base fabric across multiple SKUs.

- Batch Sample Testing: Make several styles with the same fabric and test which performs best.

- Strategic MOQ Planning: Start small, test market fit, and reorder based on sell-through rate.

How Does the Custom Bottoms Manufacturing Process Work?

If you’ve got an idea, we can bring it to life.

The process includes concept → tech pack creation → sample making → production. You’ll need sketches, preferred fabrics, target sizes, and branding materials.

Full Workflow

- Design Consultation: We discuss your vision and timeline.

- Tech Pack Development: Details like measurements, construction specs, and trims.

- Sample Development: We produce your sample for fit and quality approval.

- Bulk Order Production: Once approved, your bottoms go into full-scale production.

All this can start with just an email and a rough sketch.

Where Can You Find a Reliable Manufacturer for Custom Bottoms?

Great designs mean nothing without a strong production partner.

Look for manufacturers who specialize in bottoms, offer flexible MOQs, fast sampling, and have deep material sourcing networks.

Questions to Ask Your Factory

- Do you have experience with cargo, tailored, and stretch styles?

- How quickly can you turn around samples?

- Can you handle both woven and knit fabrics?

- Do you offer branding and labeling services?

Real Story

One of our U.S. clients scaled from a 120-piece order of custom cargo joggers to a 6-piece collection in under a year. All thanks to low-barrier testing, reliable production, and on-point trend reads.

Conclusion

With full control over fit, fabric, and finish, custom bottoms offer an unmatched opportunity to strengthen your brand and boost profit margins. If you’re looking to add something bold, exclusive, and scalable to your next collection—custom bottoms may be exactly what you need.

-

Explore how custom bottoms can elevate your brand’s identity and meet consumer demand for exclusivity. ↩