Acetate fabric, prized for its silky texture and elegant sheen, is a popular choice in women’s fashion. At Jinfeng Apparel, we use high-quality acetate to craft garments that blend comfort with sophistication. Lightweight, breathable, and vibrant, this semi-synthetic fabric is perfect for everything from formal dresses to chic everyday wear.

In this blog, we’ll explore its unique features and versatile applications in women’s fashion.

What is Acetate Fabric?

Acetate fabric is a semi-synthetic textile made from cellulose derived from wood pulp or cotton linters. Known for its smooth, glossy texture and elegant drape, acetate is often used in women’s fashion for garments that require a soft, luxurious appearance. This fabric provides an affordable alternative to silk, with a similar sheen and softness, making it a popular choice in both formalwear and everyday garments.

Origin and Source of Acetate Fibers

Acetate fibers were first developed in the early 20th century to provide a lower-cost alternative to silk. The process begins with extracting cellulose from wood pulp or cotton linters, which is then treated with acetic acid to create fibers. These fibers are spun into yarn and woven into fabric, offering a silky finish with vibrant color retention. The resulting fabric mimics the sheen and feel of natural silk but at a fraction of the cost.

Historical Significance and Modern Usage

Historically, acetate fabric was introduced to meet the demand for luxurious yet affordable textiles. Initially developed as a silk substitute, acetate became widely used in fashion due to its lightweight, breathable qualities and elegant drape. Over time, it has found its place in formalwear such as evening gowns, as well as linings in jackets and skirts. Its affordability and visual appeal make it a staple in many fashion collections.

Acetate Fabric Today

In modern fashion, acetate continues to be valued for its versatility and cost-effectiveness. It is frequently used in women’s clothing, particularly in dresses, blouses, and linings that require a polished, flowing look. At Jinfeng Apparel, we use high-quality acetate fabrics to create stylish and comfortable garments that reflect contemporary fashion trends, ensuring a balance between luxury and practicality for our consumers.

What Makes Acetate Fabric Unique?

Acetate fabric is prized for its luxurious appearance and affordability, making it a popular choice for high-end fashion that doesn’t compromise on budget. Its unique combination of silk-like qualities and practical features make it ideal for women’s fashion, where elegance and comfort are essential.

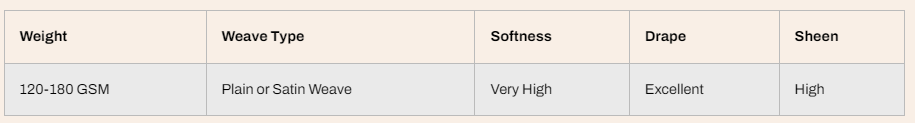

Key Characteristics and Qualities

- Silk-like Sheen and Softness: Acetate fabric closely mimics the luster and soft texture of silk. This makes it perfect for garments that require a luxurious look and feel, such as evening gowns, blouses, and scarves. It delivers high-end appeal without the high cost of silk.

- Drape and Fluidity: One of the standout qualities of acetate fabric is its ability to drape beautifully. Its flowing nature adds a sophisticated touch to women’s fashion pieces, ensuring garments like dresses and skirts move gracefully.

- Vibrant Color Retention: Acetate fabric excels at holding dyes, producing bold and vibrant colors that resist fading. This makes it a preferred fabric for designs that require bright, eye-catching hues, ensuring garments maintain their aesthetic appeal over time.

- Low Static and Comfort: Unlike some synthetic fabrics, acetate generates less static, enhancing its comfort for daily wear. This feature makes it ideal for formal or evening wear, providing both comfort and elegance.

Comparison with Other Fabrics

- Acetate vs. Silk: While both fabrics offer a luxurious sheen and softness, acetate is significantly more affordable and easier to care for than silk, which requires delicate handling and has a much higher price point.

- Acetate vs. Polyester: Polyester is known for its durability, but acetate outshines polyester in terms of drape, softness, and its ability to mimic silk’s elegant look, making acetate a better choice for garments where aesthetic appeal is key.

- Acetate vs. Rayon: Both are semi-synthetic fibers derived from cellulose, but acetate has a silkier texture and better drape, while rayon is more breathable and absorbent. Acetate is preferred for formal and high-end fashion, whereas rayon is favored for casual, breathable summer wear.

Acetate fabric stands out for its versatility, affordability, and luxurious appearance, making it a key material for fashion designers aiming to create elegant, flowing garments without compromising on cost or quality.

How is Acetate Fabric Made?

Acetate fabric is produced through a carefully controlled chemical process that transforms natural cellulose from sources like wood pulp into smooth, silk-like fibers. This method results in a luxurious fabric that is widely used in women’s fashion for its elegant drape and softness.

Production Process

- Cellulose Extraction: The production of acetate begins with the extraction of cellulose from renewable sources, typically wood pulp or cotton linters. This cellulose forms the raw material for acetate fibers.

- Acetylation: The cellulose is treated with acetic acid and acetic anhydride in a process known as acetylation. This chemical reaction transforms the cellulose into cellulose acetate, which is further processed into small flakes called acetate flakes.

- Dissolution: The acetate flakes are dissolved in a solvent like acetone to create a viscous solution. This solution is essential for the next stage, where the fibers are formed.

- Spinning: The viscous acetate solution is pushed through spinnerets—devices with small holes—to create fine filaments. These filaments are solidified either by evaporation or by being submerged in a chemical bath, which results in the formation of acetate fibers.

- Weaving or Knitting: The acetate fibers are spun into yarn and then either woven or knitted into fabric. Woven acetate fabric offers structure and is often used in formal garments, while knitted acetate is softer and used in more casual fashion pieces.

- Finishing: After weaving or knitting, the fabric undergoes finishing treatments such as dyeing and softening. These processes enhance the fabric’s texture, colorfastness, and resistance to wrinkles, ensuring that the final product is both visually appealing and functional.

Regions Known for Acetate Fabric Production

- United States: The U.S. is a key producer of high-quality acetate fabrics, especially for use in luxury and formalwear markets.

- China: A major global producer, China manufactures a wide variety of acetate fabrics, catering to both domestic and international demand with competitive pricing.

- Japan: Known for its premium acetate fabrics, Japan is recognized for producing high-end materials, particularly for luxury fashion brands.

Acetate fabric’s production process results in a textile that is celebrated for its luxurious sheen, softness, and affordability, making it a popular choice for a wide range of fashion applications from evening gowns to linings.

What Are the Types of Acetate Fabric?

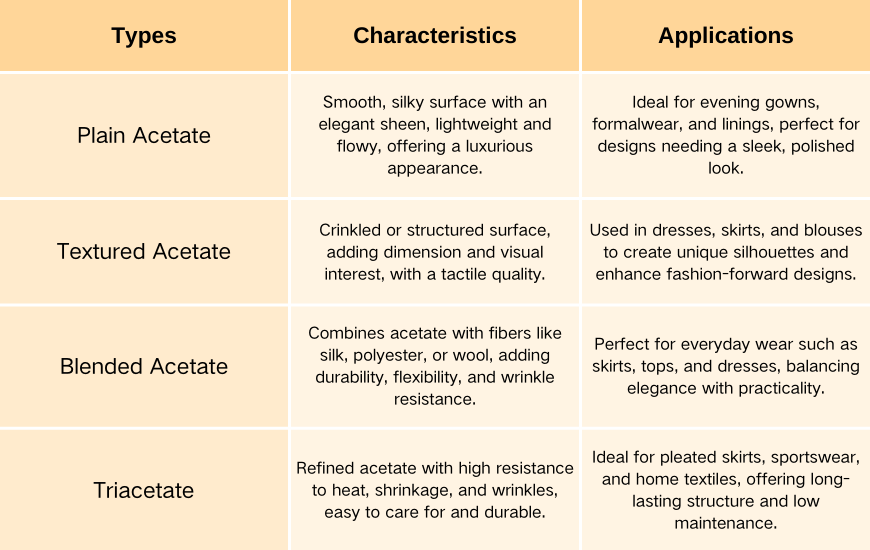

Acetate fabric comes in different variations, each tailored to suit specific fashion and textile needs. These types of acetate offer unique qualities that make them versatile for a range of applications in women’s fashion.

Plain Acetate

Plain acetate is the most commonly used type of acetate fabric, characterized by its smooth, silky surface and elegant sheen. It drapes beautifully, making it a favorite for garments like evening gowns, formalwear, and linings. Its lightweight nature and flowy appearance lend a luxurious feel to fashion designs, especially where a sleek, polished look is desired.

Textured Acetate

Textured acetate offers a crinkled or more structured surface, adding dimension and visual interest to garments. This type of acetate is used in dresses, skirts, and blouses where designers seek to create unique silhouettes or add a tactile quality to the fabric. The texture provides a striking contrast to the smoothness of plain acetate, enhancing fashion-forward designs.

Blended Acetate

Blended acetate combines acetate with other fibers like silk, polyester, or wool to improve its durability, flexibility, and resistance to wrinkling. Blends retain acetate’s natural sheen and drape while adding strength, making them ideal for everyday wear such as skirts, tops, and dresses. This blend balances elegance with practicality, offering a more versatile fabric for various fashion needs.

Triacetate

Triacetate is a chemically refined version of acetate, known for its high resistance to heat, shrinkage, and wrinkles. This type of acetate is easy to care for, making it perfect for garments that require low maintenance, such as pleated skirts, sportswear, and home textiles like curtains. Its durability and resilience make it a popular choice for garments that need to maintain structure over time.

Each type of acetate fabric serves a specific function, allowing designers to choose the appropriate variation for different fashion goals—from luxurious eveningwear to practical, everyday clothing.

How is Acetate Fabric Used in Women’s Fashion?

Acetate fabric is widely used in women’s fashion due to its luxurious feel, smooth texture, and elegant drape. Its versatility makes it an ideal choice for both casual and formal garments, adding sophistication to various styles.

Evening Wear and Formal Gowns

Acetate is frequently used for evening wear and formal gowns because of its silky, lustrous appearance. Its excellent drape makes it perfect for flowing dresses, ball gowns, and cocktail attire. The fabric’s ability to mimic the look and feel of silk at a more affordable price point makes it a popular choice for luxury-inspired designs that require elegance and sophistication.

Blouses and Dresses

The softness and fluidity of acetate make it ideal for blouses and dresses that require comfort, style, and ease of movement. Women’s fashion pieces like flowy dresses and stylish blouses benefit from acetate’s lightweight nature and its ability to hold vibrant colors, making the garments both visually appealing and comfortable to wear.

Linings for Jackets and Coats

Acetate is commonly used as a lining material for jackets, coats, and blazers. Its smooth surface allows garments to slip on easily, enhancing comfort and wearability. In women’s fashion, acetate linings add a refined touch to outerwear, ensuring the garments look polished both inside and out.

Scarves and Accessories

The luxurious sheen and softness of acetate make it a favored fabric for scarves, shawls, and other accessories. These items benefit from the fabric’s lightweight feel, making them comfortable to wear while adding a sophisticated element to outfits. The ability to hold bright, bold colors also ensures that accessories made from acetate are eye-catching and stylish.

Skirts and Casual Wear

For skirts and more casual women’s wear, acetate fabric is valued for its drapability and smooth texture. It adds a touch of elegance to everyday outfits, while still being easy to care for. The fabric’s versatility allows it to be used in a variety of styles, from pleated skirts to sleek, form-fitting garments.

Acetate fabric’s balance of luxury, practicality, and affordability makes it a staple in women’s fashion, whether for creating glamorous evening wear or enhancing the elegance of everyday pieces.

How Much Does Acetate Fabric Cost?

The cost of acetate fabric varies based on several factors, such as quality, type, and production location. Understanding these variations helps manufacturers make informed decisions when sourcing fabric for their collections.

Acetate Fabric Costs in the United States

- Basic Acetate Fabric: In the U.S., basic acetate fabric typically ranges from $6 to $12 per yard. This fabric is commonly used in linings, casual garments, and some lightweight fashion items due to its affordability and versatility.

- Premium Acetate Fabric: Premium acetate fabrics, which include blends or those with specialized finishes, range from $12 to $25 per yard. These options offer a silk-like feel, making them suitable for high-end eveningwear, gowns, and formal fashion pieces.

Acetate Fabric Costs in China

- Basic Acetate Fabric: In China, basic acetate fabric is more competitively priced, typically ranging from $3 to $8 per yard. The lower labor and production costs make China a preferred choice for manufacturers looking to source high-quality yet affordable acetate fabric.

- Premium Acetate Fabric: For premium varieties of acetate, including blends with other fibers like silk or polyester, the cost in China ranges from $8 to $15 per yard. These blends provide added durability and luxurious feel at a lower price compared to U.S. counterparts.

Factors Influencing Acetate Fabric Prices

- Blended Acetate: The cost of acetate fabric increases when blended with fibers like silk or polyester, enhancing its softness, durability, and drapability.

- Production Location: Acetate fabric is generally less expensive in China due to reduced production and labor costs, while in the U.S., higher labor standards and operational costs contribute to a higher price point.

- Certifications and Quality: Certified acetate fabrics, such as those that are OEKO-TEX® certified, may come at a higher price due to the additional steps taken to ensure environmentally friendly and safe production methods.

Comparing Acetate Fabric Prices: U.S. vs. China

Acetate fabric sourced from China is generally 20% to 40% cheaper than similar fabric sourced from the United States. This price difference makes China an attractive option for manufacturers aiming to produce high-quality garments at competitive prices.

By sourcing competitively priced acetate fabrics, Jinfeng Apparel ensures it can offer luxurious, stylish garments that appeal to consumers who value both quality and affordability.cally lower, making it a cost-effective option for women’s fashion manufacturers like Jinfeng Apparel.

How Does Acetate Fabric Impact the Environment?

The environmental impact of acetate fabric involves both positive and negative factors, depending on its production process and sustainability practices. Below is an overview of its eco-friendly aspects and challenges.

Positive Environmental Impacts

- Biodegradability: Acetate fabric, being derived from natural cellulose (usually from wood pulp), is biodegradable. This allows it to break down over time under the right conditions, reducing its long-term presence in landfills compared to synthetic fibers like polyester or nylon.

- Renewable Resource: Acetate is produced using cellulose from renewable resources like fast-growing trees such as beech or pine. This reliance on renewable materials makes it more sustainable than fully synthetic fabrics that are petroleum-based.

Negative Environmental Impacts

- Chemical Processing: Acetate production requires chemicals like acetic acid and acetone to transform cellulose into fiber. If these chemicals are not managed properly, they can contribute to environmental pollution, including water contamination and hazardous waste generation.

- Water and Energy Usage: The production of acetate fabric, particularly during processing and dyeing, consumes significant amounts of water and energy. Without proper water treatment systems, the wastewater produced can negatively impact local water sources, harming ecosystems and contributing to pollution.

Sustainable Practices

- Certifications: Acetate fabrics that hold certifications like OEKO-TEX® or Global Organic Textile Standard (GOTS) demonstrate that they meet strict environmental and ethical production standards. These certifications ensure responsible chemical use, waste management, and social responsibility.

- Water Management: Implementing closed-loop water systems and wastewater treatment during acetate production can significantly reduce water waste and prevent contamination of local water bodies. Sustainable water use is critical to minimizing the overall environmental impact of fabric production.

While acetate fabric offers eco-friendly benefits such as biodegradability and renewable sourcing, its environmental footprint is influenced by the chemicals and water resources required during production. Using sustainable practices and achieving relevant certifications can help improve its environmental performance and reduce negative impacts.

Ensuring Acetate Fabric Quality and Certification

At Jinfeng Apparel, we prioritize quality and sustainability in the production of our acetate fabrics. By adhering to strict certifications and quality control processes, we ensure that our acetate garments offer luxury, comfort, and environmental responsibility.

Key Quality Indicators

- Fiber Strength and Durability: Acetate fabric is valued for its smooth texture and fluid drape. At Jinfeng Apparel, we focus on sourcing premium acetate fibers that provide long-lasting durability and maintain their structure, ensuring that garments can withstand regular wear while preserving their elegance.

- Breathability and Comfort: Acetate is known for its softness and lightweight feel, making it ideal for fashion garments. Our meticulous production methods enhance the breathability of acetate, allowing for garments that are comfortable to wear in both formal and casual settings.

- Color Retention: One of acetate’s key qualities is its ability to hold vivid, vibrant colors. Jinfeng Apparel ensures that our acetate fabrics retain their rich hues, maintaining their beauty and visual appeal over time, even after repeated use.

Certifications and Sustainability

- OEKO-TEX® Standard 100: Our acetate fabrics meet OEKO-TEX® Standard 100 certification, guaranteeing that they are free from harmful substances and safe for direct skin contact. This certification provides peace of mind for our customers, knowing that their garments are produced according to strict safety and environmental standards.

- ISO Standards: Jinfeng Apparel adheres to ISO standards for quality management and environmental sustainability. These globally recognized benchmarks ensure that our production processes are both efficient and environmentally responsible, aligning with modern standards of excellence.

By ensuring our acetate fabrics meet these certifications and quality indicators, Jinfeng Apparel delivers garments that blend luxury, practicality, and sustainability—catering to the needs of today’s fashion-conscious and eco-aware consumers.

Explore our fabric catalog to learn more about different types of fabrics.