At JinFeng Apparel, we prioritize creating high-quality, sustainable garments that meet the modern woman’s needs.

Lyocell fabric, with its eco-friendly properties and versatile applications, plays a significant role in our collections.

In this blog, we explore the unique characteristics of Lyocell, its production process, and its application in women’s fashion.

What is Lyocell Fabric?

Lyocell fabric is a sustainable textile made from cellulose fibers derived from wood pulp, primarily sourced from eucalyptus, beech, and spruce trees. Known under the brand name Tencel™, Lyocell is celebrated for its softness, strength, and versatility. This eco-friendly fabric is produced using a closed-loop process that ensures minimal environmental impact, making it a preferred choice across various industries for its sustainability and superior qualities.

Origin and Source of Lyocell Fibers

The production of Lyocell starts with sustainably sourced wood from managed forests, mainly located in regions such as Austria, the United States, China, and India. The wood pulp is dissolved in a non-toxic solvent called N-methylmorpholine N-oxide, which is then reclaimed and reused in a closed-loop system. This process significantly reduces environmental pollution and resource waste, enhancing the fabric’s eco-friendly reputation.

Historical Significance and Modern Usage

Lyocell is a relatively modern fabric, first developed in the 1970s and commercially introduced by Lenzing AG under the brand name Tencel™. Despite its recent origins, Lyocell has quickly gained popularity due to its environmentally friendly production process and excellent properties. Today, Lyocell is extensively used in fashion, home textiles, and even medical applications, reflecting its versatility and the textile industry’s shift towards more sustainable and responsible production methods.

Lyocell Fabric Today

Modern Lyocell production continues to grow, with significant contributions from Austria, the United States, China, and India. The fabric’s sustainable qualities, such as its biodegradability and closed-loop production process, have made it increasingly popular in various sectors. As awareness of environmental issues rises, Lyocell’s eco-friendly nature is expected to drive its demand further.

At JinFeng Apparel, we harness the qualities of Lyocell to produce premium women’s fashion. By combining traditional craftsmanship with modern techniques, we meet our clients’ diverse needs, ensuring they receive products of the highest quality and sustainability.

What Makes Lyocell Fabric Unique?

Lyocell fabric is distinguished by several key attributes that make it a favored choice in women’s fashion:

- Softness and Comfort: Lyocell is renowned for its exceptionally soft texture, often likened to silk or cotton, providing a luxurious and gentle feel against the skin. This makes it ideal for creating garments that prioritize comfort.

- Breathability and Moisture-Wicking Properties: This fabric excels at absorbing moisture and allowing it to evaporate quickly, keeping the wearer cool and dry. These properties make Lyocell particularly suitable for activewear and summer clothing, where comfort and performance are paramount.

- Durability and Strength: Despite its softness, Lyocell fibers are strong and resilient, ensuring that garments made from this fabric are long-lasting and retain their quality through regular wear and washing.

- Biodegradability and Sustainability: Lyocell is produced from natural cellulose, making it biodegradable and environmentally friendly. The closed-loop production process further enhances its sustainability by recycling the solvent used in fiber production, minimizing waste and environmental impact.

Comparison with Other Fabrics

- Lyocell vs. Cotton: Lyocell offers a smoother and softer feel compared to cotton, which can reduce skin irritation. It is also more absorbent and less prone to wrinkling. Additionally, the production of Lyocell is more sustainable, requiring less water and fewer pesticides than cotton cultivation.

- Lyocell vs. Synthetic Fibers (like Polyester): While synthetic fibers like polyester are known for their durability and affordability, Lyocell provides superior breathability and a more natural, comfortable feel. Moreover, Lyocell’s biodegradability offers a significant environmental advantage over synthetic fibers, which contribute to long-term plastic pollution.

How is Lyocell Fabric Made?

Lyocell fabric, celebrated for its eco-friendly properties and high performance, is produced through a meticulous process that underscores its sustainability and quality. The production process is carefully designed to minimize environmental impact while ensuring the fabric’s superior characteristics.

- Harvesting Wood Pulp: The process begins with the sustainable harvesting of wood from managed forests, primarily involving eucalyptus, beech, and spruce trees. These trees are selected for their fast growth and renewability, making them ideal for producing eco-friendly textiles.

- Pulping the Wood: The harvested wood is chipped into small pieces and then chemically treated to extract cellulose fibers. This pulping process is crucial as it separates the cellulose, which forms the basis of Lyocell fabric.

- Dissolving Cellulose: The cellulose fibers are dissolved in N-methylmorpholine N-oxide (NMMO), a non-toxic solvent. This creates a viscous solution, which is essential for transforming the solid wood pulp into a spinnable form.

- Spinning the Fibers: The cellulose solution is extruded through spinnerets to form continuous Lyocell fibers. These fibers are then washed to remove the solvent, which is almost entirely recycled in a closed-loop system, significantly reducing environmental waste.

- Drying and Finishing: After washing, the fibers are dried and may undergo additional treatments such as bleaching, dyeing, and finishing. These processes enhance the fabric’s properties, preparing it for use in various applications, particularly in women’s fashion.

Regions Known for Lyocell Production

- Austria: Austria is renowned for producing high-quality Lyocell, particularly through Lenzing AG, the company behind Tencel™. The production here emphasizes advanced technology and sustainable practices, ensuring that the fabric meets high environmental standards.

- United States: In the U.S., Lyocell production is concentrated in areas with significant forestry resources. The focus is on innovation and sustainable practices, contributing to the global supply of this eco-friendly fabric.

- China: As a major player in the textile industry, China utilizes advanced manufacturing technologies to produce Lyocell on a large scale. The country’s extensive resources and efficiency make it a critical supplier of Lyocell fabric globally.

- India: India is emerging as a key producer of Lyocell, driven by a growing focus on sustainability and expanding production capacities. This growth is supported by both domestic demand and the country’s increasing role in the global textile market.

These regions contribute significantly to the global supply of Lyocell, each bringing unique strengths to its production. JinFeng Apparel ensures that the Lyocell used in our garments is sourced from these leading regions, guaranteeing both quality and sustainability in our products.

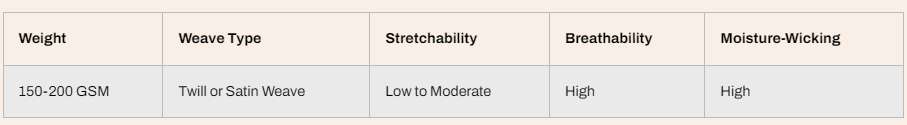

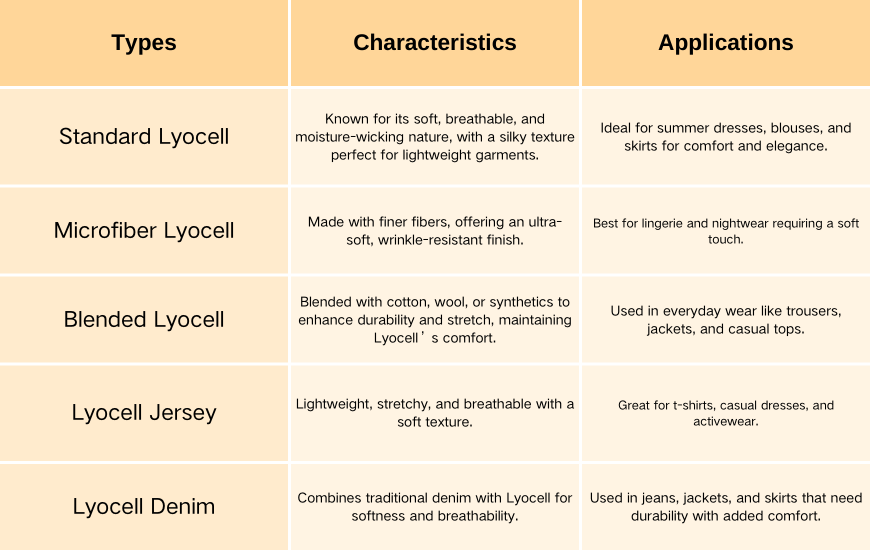

What are the Types of Lyocell Fabric?

Lyocell fabric comes in several types, each designed to meet specific needs in women’s fashion. At JinFeng Apparel, we carefully select the type of Lyocell fabric that best suits the design and functional requirements of our garments.

- Standard Lyocell: The most common type of Lyocell, known for its softness, breathability, and moisture-wicking abilities. It has a smooth, silky texture that drapes beautifully, making it ideal for lightweight garments like summer dresses, blouses, and skirts where comfort and a luxurious feel are important.

- Microfiber Lyocell: Made from finer fibers, this version has an ultra-soft and smooth finish. It is highly absorbent and wrinkle-resistant, perfect for delicate clothing like lingerie, nightwear, and intimate apparel that needs a gentle touch.

- Blended Lyocell: A combination of Lyocell with fibers like cotton, wool, or synthetics, it adds stretch or durability while maintaining comfort and eco-friendly qualities. It’s commonly used in trousers, jackets, and casual tops where durability and comfort are key.

- Lyocell Jersey: Lightweight, stretchy, and soft, Lyocell jersey offers a casual yet refined look. It retains breathability and moisture management with added stretch, making it great for t-shirts, casual dresses, and activewear.

- Lyocell Denim: Blending traditional denim with Lyocell fibers results in a softer, more breathable fabric. It keeps the rugged denim look with added comfort, perfect for women’s jeans, jackets, and skirts.

At JinFeng Apparel, we utilize these various types of Lyocell fabric to create garments that align with the modern woman’s lifestyle, ensuring that each piece is as sustainable as it is stylish.

How is Lyocell Fabric Used?

Lyocell fabric’s versatility and eco-friendly properties make it a popular choice across various segments of women’s fashion. At JinFeng Apparel, we utilize Lyocell in the following key applications:

Casual Wear:

- Application: Lyocell is commonly used in everyday casual wear due to its softness and breathability. It is perfect for t-shirts, blouses, and lightweight pants that prioritize comfort.

- Example Garments: Flowy summer tops, comfortable tees, and breathable trousers.

Activewear:

- Application: Thanks to its moisture-wicking properties and ability to regulate temperature, Lyocell is ideal for activewear. It keeps the wearer cool and dry during workouts.

- Example Garments: Yoga pants, sports bras, and performance leggings that require flexibility and moisture control.

Lingerie and Intimates:

- Application: The ultra-soft feel of Lyocell makes it an excellent choice for lingerie and intimate apparel. It is gentle on the skin and offers a luxurious touch.

- Example Garments: Nightgowns, underwear, and bralettes that emphasize comfort and softness.

Sustainable Fashion:

- Application: As a sustainable material, Lyocell is a key fabric in eco-conscious fashion collections. Its production has a low environmental impact, making it a favorite for brands focused on sustainability.

- Example Garments: Eco-friendly dresses, skirts, and tops that highlight both style and sustainability.

Formal and Office Wear:

- Application: Lyocell’s smooth texture and elegant drape make it suitable for formal wear. It provides a polished look while ensuring comfort throughout the day.

- Example Garments: Blouses, tailored dresses, and skirts designed for professional settings.

Denim Alternatives:

- Application: Lyocell is often blended with cotton to create softer, more breathable denim alternatives. It offers the classic look of denim with enhanced comfort.

- Example Garments: Soft denim jeans, skirts, and jackets that maintain the rugged appeal of denim with added comfort.

At JinFeng Apparel, we integrate Lyocell into a wide range of garments, ensuring that our collections not only offer superior comfort and style but also reflect our commitment to sustainability.

How Much Does Lyocell Fabric Cost?

The cost of Lyocell fabric varies based on factors such as quality, type, and the region where it’s sourced. Below is a detailed comparison of Lyocell fabric prices in the United States and China, reflecting both basic and specialty options.

Lyocell Fabric Costs in the United States

- Basic Lyocell Fabric: The average price for basic Lyocell fabric in the U.S. typically ranges from $10 to $20 per yard. This category includes standard Lyocell fabrics used in everyday apparel, such as t-shirts, blouses, and lightweight dresses.

- Specialty Lyocell Fabric: Specialty Lyocell fabrics, which may include blended versions or those with enhanced features like moisture-wicking or eco-certifications, can range from $25 to $40 per yard. These are often used in high-performance garments, luxury apparel, and eco-friendly fashion lines.

Lyocell Fabric Costs in China

- Basic Lyocell Fabric: In China, basic Lyocell fabric is generally priced between $5 to $12 per yard. The lower production costs and efficient manufacturing processes in China make it a competitive option for brands seeking bulk orders.

- Specialty Lyocell Fabric: Specialty Lyocell fabrics in China, such as those with advanced finishes or higher sustainability standards, typically range from $15 to $30 per yard. This pricing offers a more affordable alternative to U.S. prices without compromising on quality.

Comparing the Prices: U.S. vs. China

The cost of Lyocell fabric in China is generally 30% to 40% lower than in the United States. This significant price difference makes China an attractive sourcing destination, particularly for brands and manufacturers looking to optimize their production costs while maintaining high-quality standards.

Benefits of Sourcing Lyocell Fabric from China

Sourcing Lyocell fabric from China offers substantial cost savings without sacrificing quality. The country’s advanced manufacturing infrastructure and large-scale production capabilities ensure that the Lyocell fabric produced meets international standards, making it an excellent choice for businesses focused on both sustainability and cost-effectiveness in their women’s fashion collections.

How Does Lyocell Fabric Impact the Environment?

Lyocell fabric is widely recognized for its eco-friendly attributes, but understanding its full environmental impact requires an examination of its production processes and overall sustainability.

Sustainable Resource Use

Lyocell is derived from natural cellulose fibers, primarily sourced from sustainably managed forests. The wood pulp used to create Lyocell comes from trees like eucalyptus, which grow quickly and require fewer resources, such as water and pesticides, compared to traditional crops like cotton. This contributes to the renewable nature of Lyocell production and reduces environmental degradation from raw material sourcing.

Closed-Loop Production Process

A major environmental advantage of Lyocell fabric lies in its closed-loop production system. The process uses N-methylmorpholine N-oxide (NMMO), a non-toxic solvent, to dissolve the wood pulp. Nearly 99% of the solvent is recovered, recycled, and reused, significantly reducing chemical waste and water pollution. This method minimizes environmental harm and resource waste, making it more sustainable compared to the manufacturing of other fabrics like polyester or nylon, which rely heavily on chemicals and produce large amounts of waste.

Biodegradability

Lyocell fabric is fully biodegradable, meaning it decomposes naturally without leaving behind harmful residues. When disposed of in proper composting conditions, Lyocell can break down within a few months, unlike synthetic fabrics such as nylon, which persist in the environment for hundreds of years and contribute to long-term pollution. This biodegradability is a critical aspect of Lyocell’s reduced environmental footprint.

Water and Energy Use

While Lyocell production is more water-efficient than cotton, it does still require water for processing, particularly during the spinning and dyeing phases. However, the overall water usage is significantly lower than cotton production, which is notorious for its high water demands. Additionally, Lyocell requires less energy than synthetic fabrics, further decreasing its carbon footprint.

Chemical Usage and Safety

The chemicals used in Lyocell production, particularly NMMO, are relatively safe and non-toxic compared to the harsh chemicals often employed in the production of synthetic fabrics like nylon and polyester. This reduces the risk of harmful emissions and water contamination, enhancing the fabric’s sustainability profile.

Sustainability Commitment at JinFeng Apparel

At JinFeng Apparel, we are committed to using sustainable materials like Lyocell to minimize our environmental footprint. By partnering with responsible suppliers and utilizing eco-friendly production techniques, we ensure that our Lyocell-based garments not only meet high-quality standards but also align with our values of environmental responsibility. We invite brands to collaborate with us in producing eco-conscious, high-performance apparel that resonates with today’s environmentally aware consumers.

Ensuring Lyocell Fabric Quality and Certification

To guarantee high-quality Lyocell fabric for women’s fashion at JinFeng Apparel, it’s essential to evaluate the fabric’s performance and sustainability through key quality indicators and recognized certifications. Here’s how to ensure the best Lyocell fabric for your garments:

Key Quality Indicators

- Fiber Strength and Durability: Premium Lyocell fabric should be strong yet soft, with excellent resistance to wear and tear. The fibers should be tightly woven, offering both flexibility and longevity, especially in activewear and everyday apparel.

- Color Fastness: Lyocell fabric should maintain its vibrant color after multiple washes. High-quality fabric will resist fading and ensure long-lasting aesthetics, critical in fashion applications.

- Moisture-Wicking and Breathability: One of Lyocell’s main advantages is its moisture-wicking properties. Ensure the fabric effectively absorbs moisture, keeping the wearer dry and comfortable, especially important in summer and activewear collections.

- Softness and Drape: Lyocell is known for its silky smooth texture and elegant drape. Quality fabric should maintain these characteristics even after extensive use, providing comfort and sophistication in women’s fashion.

Certifications for Lyocell Fabric

- OEKO-TEX® Standard 100: This certification guarantees that Lyocell fabric is free from harmful substances and safe for human use. It’s essential in ensuring fabric safety and environmental standards.

- FSC (Forest Stewardship Council) Certification: This certification verifies that the wood pulp used to make Lyocell is sourced from sustainably managed forests, ensuring responsible forestry practices that protect the environment.

- Global Organic Textile Standard (GOTS): For organic variants of Lyocell, GOTS certification ensures that the fabric is made from organically sourced fibers and meets strict environmental and social criteria throughout production.

- ISO Standards for Textile Quality (ISO 9001): This certification indicates that the Lyocell fabric has been produced under a quality management system that meets international standards, ensuring consistent quality and performance.

At JinFeng Apparel, we prioritize working with suppliers who meet these high standards, ensuring that our Lyocell garments not only deliver superior quality but also align with our commitment to sustainability and eco-friendly fashion.

By focusing on these quality indicators and certifications, JinFeng Apparel guarantees that our Lyocell-based products maintain the highest standards of both style and environmental responsibility.

Explore our fabric catalog to learn more about different types of fabrics.