Gore-Tex fabric is a high-performance, waterproof, and breathable material, renowned for its ability to withstand extreme weather conditions.

Originally developed for outdoor gear, it has evolved into a key fabric in women’s fashion, especially for activewear and outerwear.

In this blog, we explore the unique properties of Gore-Tex, its production process, applications in women’s fashion, and its environmental impact.

What is Gore-Tex Fabric?

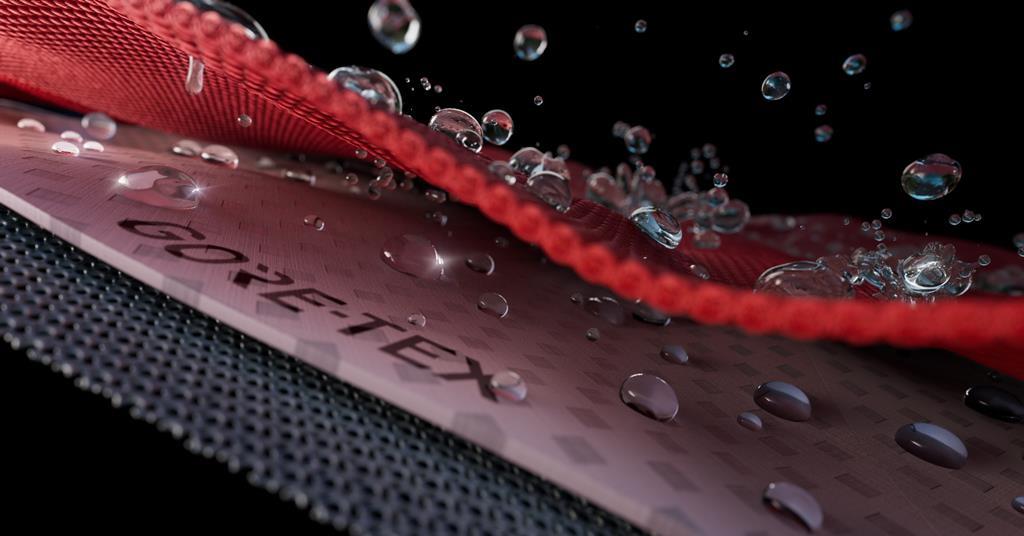

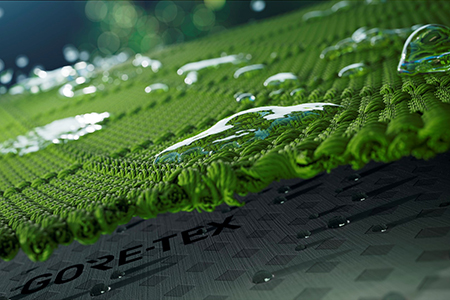

Gore-Tex fabric is a high-performance material renowned for its waterproof, windproof, and breathable qualities, crafted from expanded polytetrafluoroethylene (ePTFE). Originally developed by Robert W. Gore in the 1970s, this fabric revolutionized the outdoor and performance apparel industry by offering protection against the elements while maintaining comfort. Its innovative membrane structure contains millions of microscopic pores that are small enough to prevent water droplets from penetrating but large enough to allow moisture vapor to escape, ensuring wearers stay dry and comfortable.

Origin and Production of Gore-Tex Fabric

Gore-Tex fabric was created when Robert W. Gore discovered that stretching PTFE could produce a breathable, durable membrane known as ePTFE. The production process involves expanding PTFE to form the ePTFE membrane, which is then bonded with other textiles to enhance its properties. The key to its functionality lies in its microscopic pores—these are 20,000 times smaller than a water droplet but 700 times larger than a vapor molecule, allowing the fabric to block rain while letting vapor escape, making it both protective and comfortable.

Historical Significance and Modern Usage

Since its debut in the 1970s, Gore-Tex fabric has been instrumental in transforming outdoor gear and activewear. Initially embraced by hikers, climbers, and outdoor enthusiasts for its ability to keep them dry in unpredictable weather, Gore-Tex has become a staple in high-performance apparel. Its moisture management and protection capabilities have expanded its use into a variety of garments, including jackets, gloves, and footwear designed for active and outdoor lifestyles.

Gore-Tex Fabric Today

In modern fashion, Gore-Tex fabric continues to dominate the market for performance and activewear. It is now used in a wide range of women’s fashion items, from stylish rain jackets and winter coats to ski outfits and outdoor boots. At Jinfeng Apparel, we utilize high-quality Gore-Tex fabrics to craft elegant, functional garments that cater to the needs of active women, ensuring they stay protected and comfortable, no matter the conditions.

What Makes Gore-Tex Fabric Unique?

Gore-Tex fabric stands out for its advanced technology, combining comfort, protection, and performance. It is a go-to choice for active and outdoor apparel, providing unmatched versatility and reliability. Below are the key characteristics that make Gore-Tex fabric exceptional:

Key Characteristics and Qualities

- Waterproof and Breathable: The unique microporous membrane of Gore-Tex blocks water droplets from penetrating while allowing moisture vapor (such as sweat) to escape. This ensures that wearers stay dry and comfortable, even during intense physical activities or in wet conditions.

- Windproof: Gore-Tex fabric also offers windproof protection, effectively preventing wind from penetrating the fabric and causing heat loss. This makes it ideal for outdoor activities in windy or harsh climates, helping maintain body warmth.

- Durability: Known for its strength, Gore-Tex fabric is highly resistant to tears, abrasions, and general wear. This durability ensures that garments made from Gore-Tex withstand the rigors of activities like hiking, skiing, and mountaineering.

- Lightweight: Despite its robust protective qualities, Gore-Tex remains lightweight, allowing for ease of movement and comfort. This characteristic is crucial for activewear and performance garments, where flexibility and mobility are essential.

Comparison with Other Fabrics

- Gore-Tex vs. Nylon: While nylon is durable, it lacks the waterproof and breathable properties of Gore-Tex. Gore-Tex’s membrane offers superior protection against water while maintaining comfort, making it more suitable for high-performance outdoor gear.

- Gore-Tex vs. Polyester: Polyester is lightweight but often lacks the waterproof capabilities inherent in Gore-Tex. Gore-Tex provides comprehensive weather protection, whereas polyester may require additional treatments to achieve similar water resistance.

- Gore-Tex vs. Rubber: Although rubber is waterproof, it is not breathable, making it uncomfortable for prolonged wear. In contrast, Gore-Tex combines waterproofing with breathability, ensuring that garments remain comfortable during active use.

Gore-Tex fabric’s balance of waterproofing, breathability, wind resistance, durability, and lightweight qualities make it a staple in the outdoor and activewear apparel industries.

How is Gore-Tex Fabric Made?

The production of Gore-Tex fabric involves a highly specialized process that transforms polytetrafluoroethylene (PTFE) into a breathable, waterproof, and windproof material. The following outlines the steps in the creation of this advanced textile:

Production Process

- Polymerization: The process starts with polymerizing PTFE, a durable synthetic polymer. PTFE is the primary material for Gore-Tex because of its exceptional strength, flexibility, and chemical resistance.

- Expansion: The PTFE is then expanded through a process called rapid stretching under controlled temperatures, resulting in expanded PTFE (ePTFE). This expansion creates a membrane containing millions of microscopic pores. The pores are small enough to block water droplets but large enough to allow moisture vapor (sweat) to pass through, ensuring the fabric is both waterproof and breathable.

- Lamination: The ePTFE membrane is laminated onto fabric layers such as nylon or polyester, which act as the outer shell, and inner linings that enhance comfort. These additional layers protect the membrane and add durability to the final product. For specific applications like jackets, gloves, or footwear, various configurations and extra protective layers are used to meet performance requirements.

- Finishing: The laminated fabric undergoes finishing treatments, such as applying a durable water-repellent (DWR) coating. This coating boosts the fabric’s water resistance, allowing it to repel water droplets on the surface while maintaining breathability. Gore-Tex fabric also undergoes rigorous testing to ensure it meets strict quality and performance standards.

Regions Known for Gore-Tex Fabric Production

- United States: The primary producer of Gore-Tex, focusing on high-performance textiles for outdoor, military, and industrial applications.

- Japan: Contributing to the production of Gore-Tex, Japan is known for its cutting-edge textile technology and high-quality garment manufacturing.

- Europe: Several European countries produce Gore-Tex products, particularly those aimed at professional outdoor gear and high-end sportswear.

This meticulous production process ensures that Gore-Tex fabric remains a trusted choice in the outdoor and performance apparel industry, known for its unparalleled waterproof, breathable, and durable properties.

What Are the Types of Gore-Tex Fabric?

Gore-Tex fabric is available in several specialized types, each tailored to meet the demands of different activities and weather conditions. These variations offer options for everything from extreme sports to everyday wear, ensuring versatility and performance.

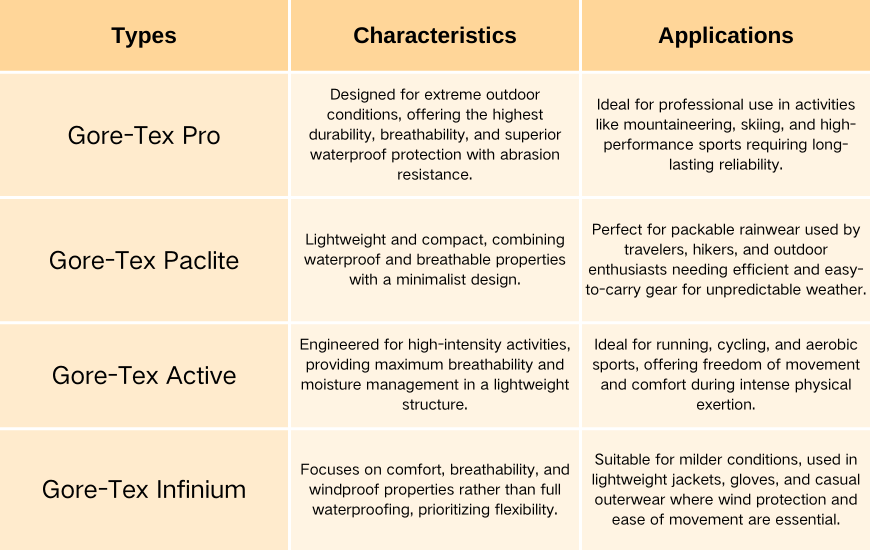

Gore-Tex Pro

Gore-Tex Pro is designed for professional use and extreme outdoor conditions. It offers the highest level of durability and breathability, making it suitable for activities such as mountaineering, skiing, and other high-performance sports. This variant provides superior waterproof protection and abrasion resistance, ensuring long-lasting reliability even in the harshest environments.

Gore-Tex Paclite

Gore-Tex Paclite is a lightweight and compact option, perfect for those who need packable rainwear. It combines the waterproof and breathable properties of Gore-Tex with a minimalist design, making it ideal for travelers, hikers, and outdoor enthusiasts who require protection without added bulk. It’s a go-to choice for those who need gear that is easy to carry and efficient for unpredictable weather.

Gore-Tex Active

Specifically engineered for high-intensity activities like running, cycling, and aerobic sports, Gore-Tex Active offers maximum breathability and a lightweight structure. It ensures wearers remain dry and comfortable by efficiently wicking away moisture during physical exertion. This version is ideal for athletes who need gear that provides freedom of movement and moisture management during intense workouts.

Gore-Tex Infinium

Gore-Tex Infinium is designed with a focus on comfort and breathability, prioritizing windproof properties over full waterproofing. It is ideal for garments used in milder conditions where wind protection, flexibility, and comfort are more critical. This type is commonly found in lightweight jackets, gloves, and casual outerwear, where full water resistance is not necessary but weather protection and ease of movement are essential.

Each type of Gore-Tex fabric offers specific benefits, making it a versatile and adaptable choice for various applications, from high-performance outerwear to everyday functional fashion pieces.

How is Gore-Tex Fabric Used in Women’s Fashion?

Gore-Tex fabric is a premium choice in women’s fashion, particularly for activewear and outerwear, due to its waterproof, windproof, and breathable properties. This high-performance material allows designers to create functional and stylish garments suitable for various outdoor activities and everyday wear.

Outerwear

Gore-Tex is extensively used in women’s jackets, parkas, and raincoats designed for outdoor activities such as hiking, running, and skiing. The fabric’s ability to repel water while allowing moisture vapor to escape ensures that wearers stay dry and comfortable. This makes Gore-Tex outerwear ideal for those who need reliable protection against harsh weather without compromising style or comfort.

Footwear

Women’s outdoor and athletic footwear often features Gore-Tex technology. It is integrated into hiking boots, running shoes, and winter footwear to provide waterproof protection and breathability. By keeping feet dry and comfortable during long hikes or intense workouts, Gore-Tex footwear enhances performance and ensures comfort in diverse conditions.

Activewear

For high-intensity sports like cycling, jogging, and outdoor training, Gore-Tex is incorporated into leggings, tops, and windbreakers. Its lightweight yet protective properties allow for freedom of movement while maintaining breathability and weather resistance. This makes Gore-Tex activewear a popular choice for women who engage in dynamic outdoor activities.

Accessories

Gore-Tex is also used in women’s fashion accessories, including gloves, hats, and scarves. These items benefit from the fabric’s ability to block wind and moisture while maintaining breathability, ensuring warmth and comfort in cold and wet conditions. This makes them essential for winter sports and other outdoor adventures.

Gore-Tex fabric’s versatility in women’s fashion demonstrates its ability to combine function with style, making it a trusted choice for modern, active women who seek high-performance garments suitable for both outdoor adventures and daily wear.

How Much Does Gore-Tex Fabric Cost?

The cost of Gore-Tex fabric varies based on factors such as type, quality, and production location. Understanding these variations is essential for manufacturers aiming to source the most suitable option for their needs.

Gore-Tex Fabric Costs in the United States

- Standard Gore-Tex Fabric: Prices typically range from $70 to $200 per yard, depending on the specific type (e.g., Gore-Tex Paclite or Gore-Tex Active). These prices reflect the fabric’s advanced waterproof and breathable technology, making it a popular choice for high-end outdoor and activewear, such as jackets and pants.

- Premium Gore-Tex Variants: Specialized versions like Gore-Tex Pro, designed for extreme weather conditions, and Gore-Tex Infinium, focused on comfort and flexibility, can cost upwards of $200 per yard. These variants are tailored for performance-driven apparel and luxury outdoor gear, offering enhanced durability and functionality.

Gore-Tex Fabric Costs in China

- Standard Gore-Tex Fabric: In China, prices are generally more competitive, ranging from $50 to $150 per yard. Lower labor and production costs contribute to this pricing, making China a viable sourcing option for budget-conscious manufacturers without sacrificing quality.

- Premium Gore-Tex Variants: High-performance versions, such as those for extreme outdoor applications, are priced between $100 and $180 per yard in China. Even with lower production costs, these fabrics maintain stringent performance and quality standards comparable to those produced in the United States.

Factors Influencing Gore-Tex Fabric Prices

- Type of Gore-Tex: Different variants, such as Gore-Tex Paclite (lightweight) and Gore-Tex Pro (designed for extreme conditions), vary in cost. Heavier, more robust options tend to be more expensive due to the specialized materials and construction processes involved.

- Production Location: Gore-Tex fabric produced in China benefits from lower manufacturing and labor costs, making it more affordable compared to those produced in the U.S., where higher labor standards and quality controls are applied.

- Certifications and Quality Control: Gore-Tex fabrics that meet specific performance standards or certifications may have higher prices. This reflects the advanced technology and rigorous testing required to guarantee the fabric’s durability, breathability, and waterproof performance.

Comparing Gore-Tex Fabric Prices: U.S. vs. China

Gore-Tex fabric prices in China are generally 20% to 40% lower than in the United States due to reduced production expenses. This price difference allows manufacturers to source high-quality Gore-Tex fabrics while managing costs effectively. Jinfeng Apparel leverages competitive pricing strategies to offer premium, performance-driven garments that cater to both luxury and cost-conscious consumers.

How Does Gore-Tex Fabric Impact the Environment?

Gore-Tex fabric offers both environmental advantages and challenges, influenced by its synthetic nature and production processes. Below is an analysis of its environmental impact:

Positive Environmental Impacts

- Durability: One of the strongest benefits of Gore-Tex is its longevity. Garments made with this fabric are designed to withstand harsh conditions and frequent use, leading to a longer lifespan. This durability reduces the frequency of replacements, helping to minimize textile waste and conserve resources over time.

- Lower Water Usage: Unlike the production of natural fibers such as cotton, manufacturing Gore-Tex consumes significantly less water. This reduced water usage benefits regions with limited water resources, making Gore-Tex a more sustainable option in terms of water conservation.

Negative Environmental Impacts

- Chemical Processing: The production of Gore-Tex involves using polytetrafluoroethylene (PTFE), a synthetic polymer that requires chemical processing. This often includes the application of durable water-repellent (DWR) treatments containing perfluorochemicals (PFCs). PFCs are persistent in the environment and can accumulate in water and soil, posing risks to both ecosystems and human health if not managed responsibly.

- Non-Biodegradable: Gore-Tex is not biodegradable, meaning it does not naturally break down when disposed of. Without proper recycling programs, Gore-Tex products can contribute to long-term landfill waste, presenting a significant environmental challenge.

Sustainable Practices

- Recycling Initiatives: Gore-Tex has implemented recycling programs aimed at reprocessing used garments and the PTFE material to extend the lifecycle of the fabric. While these efforts are a step toward sustainability, the recycling process for PTFE is complex and not yet widely accessible, limiting its large-scale impact.

- PFC-Free Innovations: To address the environmental concerns associated with PFCs, Gore-Tex has been developing PFC-free DWR coatings and exploring eco-friendlier alternatives. These innovations aim to maintain the fabric’s waterproof and breathable properties while reducing its chemical footprint.

Overall, while Gore-Tex fabric offers durability and water conservation benefits, the environmental impact remains influenced by its synthetic nature and the use of chemicals. Sustainable innovations and recycling programs are essential steps toward minimizing these effects and promoting a more eco-friendly approach to high-performance textiles.

Ensuring Gore-Tex Fabric Quality and Certification

At Jinfeng Apparel, we are dedicated to maintaining the highest quality standards and sustainability practices for our Gore-Tex garments, ensuring they deliver exceptional performance while meeting environmental guidelines.

Key Quality Indicators

- Durability and Performance: Gore-Tex is known for its robust and long-lasting properties. At Jinfeng Apparel, we source premium Gore-Tex materials to guarantee that our products withstand extreme conditions and frequent use, providing reliable protection for active women who engage in outdoor pursuits.

- Waterproof and Breathable: A hallmark of Gore-Tex is its ability to keep water out while allowing breathability. We ensure our Gore-Tex garments offer the perfect combination of waterproofing and ventilation, making them suitable for women’s activewear and outerwear that require all-weather functionality and comfort.

- Windproofing and Flexibility: Our Gore-Tex fabrics are designed to block wind effectively, providing an extra layer of insulation. This windproof feature enhances comfort during outdoor activities like hiking, running, and cycling, ensuring that our garments keep wearers protected and comfortable.

Certifications and Sustainability

- OEKO-TEX® Certification: All Gore-Tex fabrics used at Jinfeng Apparel are OEKO-TEX® Standard 100 certified, ensuring that they are free from harmful substances. This certification guarantees that our products are safe for the skin and meet international health and environmental standards.

- ISO Standards Compliance: We adhere to ISO standards for both quality management and environmental responsibility. By following these globally recognized standards, Jinfeng Apparel ensures that our Gore-Tex manufacturing processes maintain consistency in quality while minimizing the environmental footprint.

By upholding these certifications and implementing rigorous quality controls, Jinfeng Apparel ensures that our Gore-Tex garments provide superior functionality, comfort, and protection, while also supporting sustainable and eco-conscious practices.uction.

Explore our fabric catalog to learn more about different types of fabrics.