Professional Custom Bottoms Manufacturer

Welcome to JF Apparel, where we are committed to providing you with high-quality custom bottoms. As a leading apparel manufacturer, we focus on details and functionality, ensuring that each product is not only stylish but also comfortable and practical. Whether you need tailored trousers, joggers, or trendy leggings, our professional team delivers precise custom services to meet your specific requirements. We adhere to high craftsmanship standards and are dedicated to offering efficient and expert solutions that help your brand stand out from the competition.

Choose JF Apparel for quality, innovation, and a trusted partnership. Contact us today for free samples or product design renderings!

You can select any custom bottoms style, and we’ll take care of the rest to bring your ideas to life.

Discover our top-selling bottoms collection, all customizable to suit your brand’s identity. With a skilled team of designers, engineers, and production experts, we guide you from initial concept to finished product. Leveraging our advanced equipment and attention to detail, we ensure quality and craftsmanship at every step, delivering tailored bottoms that exceed expectations.

a red bottom

bottom bell jeans

bell bottom

bell bottom leggings

bottom lift leggings

cotton bottom

pink bell bottom

bell bottom jumpsuit

white jeans bell bottom

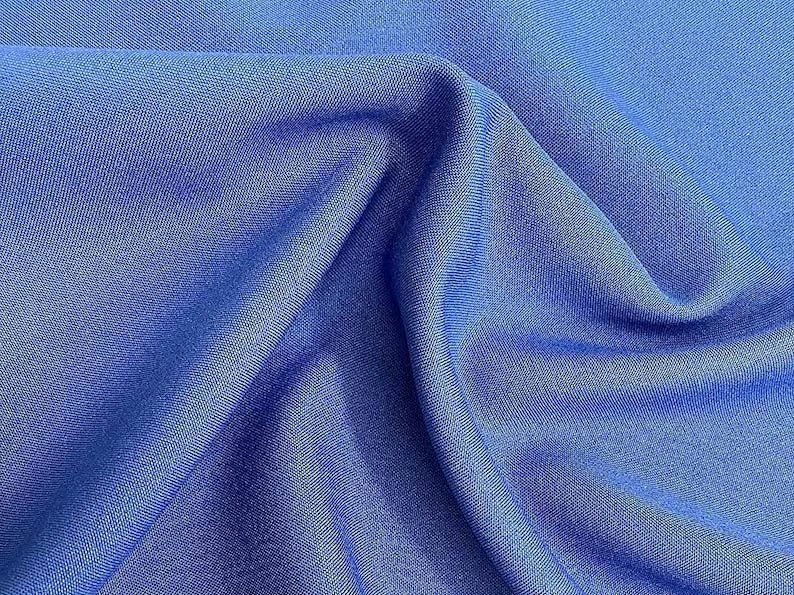

Fabrics Used for Custom Bottoms

As your reliable custom bottoms manufacturer, we understand that selecting the right fabric is essential for your project. Whether you’re looking for flexibility, durability, breathability, or specific customization options, we have a wide range of materials to meet your needs.

Cotton

Performance:Cotton is a natural fiber known for its breathability, softness, and comfort. It allows air to circulate, keeping the wearer cool and reducing moisture buildup, making it ideal for everyday wear. Cotton bottoms also provide moderate stretch, depending on the weave, ensuring flexibility without sacrificing durability.

Advantages:

- Breathability: Cotton allows air to pass through, making it ideal for warm-weather clothing.

- Softness: Gentle on the skin, cotton is comfortable for prolonged wear.

- Durability: With proper care, cotton bottoms can withstand frequent washing and wearing without losing shape or softness.

- Moisture Absorption: Cotton effectively absorbs moisture, keeping the wearer dry in humid or active conditions.

- Hypoallergenic: Cotton is less likely to cause irritation or allergic reactions, making it a good choice for sensitive skin.

- Eco-Friendly: As a natural fiber, cotton is biodegradable and can be sustainably sourced.

Composition:Cotton fabric used in custom bottoms typically consists of 100% pure cotton or a blend with materials such as spandex (for added stretch) or polyester (for increased durability and wrinkle resistance). Cotton blends enhance specific properties while maintaining cotton’s softness and breathability.

Polyester

Performance:Polyester is a synthetic fiber known for its strength, durability, and resistance to wrinkles, shrinking, and stretching. It is lightweight yet robust, making it ideal for custom bottoms that need to withstand frequent use. Polyester fabric dries quickly and retains its shape even after multiple washes, providing long-lasting performance.

Advantages:

- Durability: Polyester is highly resistant to wear and tear, making it suitable for bottoms that require long-lasting use.

- Quick-Drying: Polyester wicks moisture away from the skin and dries quickly, making it a great choice for activewear and outdoor use.

- Wrinkle-Resistance: The fabric maintains a smooth, crisp look, even after extended wear, without the need for ironing.

- Shape Retention: Polyester maintains its structure and does not easily stretch or shrink, ensuring a consistent fit over time.

- Lightweight: Despite its strength, polyester is lightweight, adding to the comfort and ease of wear for bottoms.

- Stain Resistance: Polyester fibers naturally resist staining, making maintenance easier.

- Color Retention: Polyester holds dye well, ensuring that colors remain vibrant even after repeated washing.

Composition:Polyester fabric used in custom bottoms can be made from 100% polyester or blended with other fibers such as cotton (for added breathability and softness) or spandex (for added stretch and flexibility). Polyester blends are often preferred for creating bottoms that balance comfort, durability, and versatility.

Spandex

Performance:Spandex, also known as elastane or Lycra, is a synthetic fiber renowned for its exceptional elasticity. It can stretch up to 5–8 times its original size and still return to its original shape, making it an ideal material for custom bottoms that require flexibility and a close fit. Spandex provides comfort and freedom of movement, making it a common component in activewear, leggings, and other performance-oriented bottoms.

Advantages:

- High Elasticity: Spandex offers unparalleled stretch, ensuring a snug yet comfortable fit that adapts to body movements.

- Shape Retention: Despite its stretchability, spandex returns to its original shape, preventing sagging or bagginess even after extended use.

- Comfort: The flexibility of spandex makes it ideal for bottoms that require a tight fit while allowing unrestricted movement, making it popular for athletic and form-fitting wear.

- Lightweight: Spandex is extremely lightweight, adding minimal bulk while providing significant stretch.

- Breathability: When blended with other fabrics, spandex enhances breathability, ensuring comfort during physical activities.

- Durability: Despite its softness and flexibility, spandex is highly resistant to wear and tear, making it durable over time.

Composition:Spandex is rarely used on its own; it is typically blended with other fibers such as cotton, polyester, or nylon to enhance the stretchability of these fabrics. In custom bottoms, spandex is often used in small percentages (usually 3–10%) to add elasticity while maintaining the primary characteristics of the base fabric. For example, a cotton-spandex blend would offer the softness of cotton with the added flexibility of spandex.

Nylon

Performance:Nylon is a synthetic fiber known for its exceptional strength, durability, and resistance to wear. It is lightweight, smooth, and dries quickly, making it an excellent choice for custom bottoms that need to withstand rigorous activity or harsh conditions. Nylon is also highly resistant to abrasions, making it ideal for bottoms designed for outdoor or active use.

Advantages:

- Durability: Nylon is one of the strongest synthetic fibers, making it resistant to tearing and abrasion. It holds up well in demanding environments.

- Lightweight: Despite its strength, nylon is very light, providing comfort and ease of movement without adding bulk to the garment.

- Moisture-Wicking: Nylon naturally repels water and dries quickly, making it an excellent fabric for activewear, outdoor bottoms, or any situation where moisture management is important.

- Stretch & Flexibility: Nylon provides a moderate level of stretch, often enhanced when blended with spandex, ensuring comfort and ease of movement in fitted bottoms.

- Resistant to Wrinkles and Shrinking: Nylon resists wrinkles, keeping bottoms looking fresh without the need for frequent ironing. It also maintains its shape well after washing.

- Resistant to Fading: Nylon holds dye well, maintaining vibrant colors over time, even after multiple washes.

- Easy to Clean: Nylon is stain-resistant and easy to care for, making it low-maintenance and suitable for bottoms that require frequent use.

Composition:Nylon is often used in blends with other fibers such as spandex (for added stretch) or polyester (for enhanced durability). In custom bottoms, nylon is commonly found in athletic wear, outdoor pants, and performance-based garments. Blends like nylon-spandex or nylon-polyester provide a balance of strength, flexibility, and comfort, making them suitable for a variety of activities.

Wool

Performance:Wool is a natural fiber known for its excellent insulation, breathability, and moisture-wicking properties. It keeps the wearer warm in cold conditions while remaining breathable, making it an ideal choice for custom bottoms designed for cooler weather or formal settings. Wool is also naturally resistant to wrinkles and odors, providing a durable and comfortable option for long-term wear.

Advantages:

- Insulation: Wool is highly effective at retaining heat, making it perfect for bottoms used in cold weather or winter wear. It provides warmth without being overly bulky.

- Breathability: Despite its warmth, wool is highly breathable, allowing air circulation and preventing overheating.

- Moisture-Wicking: Wool naturally absorbs moisture away from the skin while keeping the wearer dry, ensuring comfort in various conditions.

- Odor-Resistant: Wool has natural anti-microbial properties that prevent odor buildup, making it an excellent option for long-lasting wear without frequent washing.

- Wrinkle-Resistant: Wool fibers are naturally elastic, so wool garments tend to hold their shape well and resist wrinkling, reducing the need for frequent ironing.

- Durability: Wool is strong and can withstand significant wear, making it a durable fabric for formal trousers, dress pants, or winter bottoms.

- Softness (depending on type): High-quality wool, such as merino wool, is known for its softness, offering comfortable wear without the itchiness often associated with lower-grade wool.

Composition:Wool used in custom bottoms can be 100% wool or blended with other fibers to enhance specific properties. Common blends include wool with polyester (for increased durability) or wool with spandex (for added stretch and comfort). Fine-quality wool, such as merino wool, is often used in premium custom bottoms due to its softness and luxurious feel.

Denim

Performance:Denim is a durable, heavy-weight cotton fabric known for its long-lasting wear and rugged style. Traditionally woven in a twill pattern, denim provides excellent strength and durability, making it ideal for custom bottoms that are designed to withstand daily wear and tear. Over time, denim molds to the body for a personalized fit, making it popular for casual and versatile bottoms like jeans.

Advantages:

- Durability: Denim is extremely strong and resistant to abrasion, making it suitable for bottoms that require long-term use, such as jeans and workwear.

- Comfort: Despite its sturdiness, denim softens with wear, becoming more comfortable over time as it molds to the body for a custom fit.

- Versatile Style: Denim is highly versatile, allowing for a wide range of styles, from casual to more structured, depending on the weight and wash of the fabric.

- Breathability: Denim, especially 100% cotton varieties, offers good breathability, making it comfortable for long-term wear in various climates.

- Wrinkle-Resistant: The twill weave of denim makes it naturally resistant to wrinkles, keeping custom bottoms looking neat without constant ironing.

- Fading and Aging Effect: Denim develops a unique appearance over time, with fades and creases that add character to the fabric, which is a desired aesthetic for many wearers.

- Low Maintenance: Denim is relatively easy to care for, with most varieties being machine washable and requiring minimal upkeep.

Composition:Denim is traditionally made from 100% cotton, but modern denim often includes blends with fibers like polyester (for added strength) or spandex (for flexibility and stretch). Stretch denim, which incorporates a small percentage of spandex (usually around 2-3%), offers enhanced comfort and freedom of movement. Denim weights can vary, ranging from lightweight options suitable for warm-weather wear to heavier varieties designed for durability and protection.

Corduroy

Performance:Corduroy is a textured fabric known for its signature ridges, called “wales,” which create a soft, velvety feel and add a distinctive visual appeal. It is durable, warm, and slightly elastic, making it suitable for custom bottoms intended for cooler weather or casual wear. The ridges give the fabric a unique texture, which enhances the design and offers a vintage or retro aesthetic, depending on how it’s styled.

Advantages:

- Soft Texture: The velvety texture of corduroy makes it comfortable to wear, providing a soft feel against the skin, while the distinctive wales add an extra layer of texture and warmth.

- Durability: Corduroy is woven in a strong, durable structure, making it resistant to wear and tear. This makes it ideal for bottoms that will experience frequent use.

- Warmth: Due to its thicker weave and pile structure, corduroy provides good insulation, making it a great option for cooler climates or seasonal wear.

- Flexibility: Corduroy can have slight stretch depending on the weave, allowing for comfortable movement in custom bottoms.

- Versatile Style: Available in a variety of wale sizes, corduroy can be styled for casual or semi-formal settings, offering a retro-inspired or classic look. It pairs well with a range of outfit styles.

- Breathability: Though thicker than many fabrics, corduroy still offers decent breathability, ensuring comfort over prolonged periods of wear.

Composition:Corduroy is typically made from 100% cotton, but modern corduroy blends can include polyester or spandex for added stretch, strength, and flexibility. The width of the wales (ridges) can vary, with wider wales being more casual and bold, while narrow wales create a more refined, formal look. Corduroy’s pile fabric is created by weaving extra sets of fibers into the base, which are then cut to create the ribbed surface.

Rayon

Performance:Rayon is a semi-synthetic fiber made from natural cellulose, typically derived from wood pulp. It has a soft, silky texture and drapes beautifully, making it a popular choice for custom bottoms that require a flowing, lightweight, and comfortable fit. Rayon is breathable and absorbs moisture well, which makes it suitable for warm-weather or casual bottoms.

Advantages:

- Softness: Rayon is known for its smooth, silky texture, providing a comfortable feel against the skin, making it ideal for custom bottoms where comfort is a priority.

- Breathability: Rayon allows air to circulate, making it a great fabric for warm weather or humid conditions. It helps the wearer stay cool and comfortable.

- Drape: Rayon drapes elegantly, giving custom bottoms a flowing, flattering look. This makes it a great choice for relaxed-fit trousers, wide-leg pants, and more casual, loose-fitting designs.

- Moisture Absorption: Rayon has excellent moisture-wicking properties, absorbing sweat and keeping the wearer dry, which adds to the overall comfort of the garment.

- Lightweight: Rayon is lightweight, offering a soft and airy feel, which enhances its suitability for summer bottoms or more casual, relaxed styles.

- Versatile: Rayon can be easily dyed, offering vibrant and long-lasting color options, allowing for a range of design possibilities.

Composition:Rayon is derived from cellulose fibers found in wood pulp, often from beech, pine, or bamboo. It is produced through a chemical process that turns natural cellulose into a soft, smooth fiber. While rayon is breathable and absorbent like cotton, it mimics the drape and softness of silk, making it a highly versatile fabric for custom bottoms. Rayon can also be blended with other fibers such as cotton or spandex to enhance durability or add stretch.

Free Pantone Color Selection for Custom Bottoms

Explore our wide selection of fabric Pantone color options specifically designed for your custom bottoms. To streamline your decision-making process, we have thoughtfully curated a comprehensive fabric color chart. This visual tool helps you easily envision the perfect color scheme for your project, whether you’re looking for bold, fashion-forward shades or subtle, classic tones.

- Color Categories: Our fabric color chart is divided into distinct categories for easy navigation. Whether you prefer vibrant colors, neutral tones, or modern monochromes, our diverse selection ensures you can find the perfect match for your custom bottoms.

- Color Swatches: Within each category, you’ll find an array of color swatches representing the full spectrum of available shades. From dynamic and daring to soft and understated, these swatches allow you to visualize the precise hues that will bring your custom bottoms to life.

- Color Codes: Every swatch comes with a detailed color code, providing you with accuracy and consistency when making your selections. These codes ensure your final product reflects exactly the color palette you envisioned.

- Customization Options: Beyond our standard offerings, we provide custom color options for those seeking a more personalized approach. Simply provide your desired color specifications, and our team will work closely with you to create unique custom bottoms that reflect your brand’s identity.

- Digital Rendering: Unsure how your colors will look in action? Leverage our digital rendering services for a preview of your design. This allows for fine-tuning before production, ensuring your custom bottoms meet your exact expectations.

Product Details of Custom Bottoms

Creating high-quality custom bottoms requires a perfect combination of skilled craftsmanship and modern technology, ensuring a seamless integration of functionality and style in every garment. Here’s a detailed look into the precision and care that define our custom bottoms production process.

Premium Fabric

Durable Waistband

High-Quality Stitching

Elasticated Cuffs

Two Side Pockets

Reinforced Seams

Adjustable Drawstring

Elastic Waistband

Zipper Fly Closure

Breathable Mesh Lining

Hidden Inner Pocket

Foldable Design for Easy Packing

Tapered Leg Design

Moisture-Wicking Fabric

Stretchable Fabric

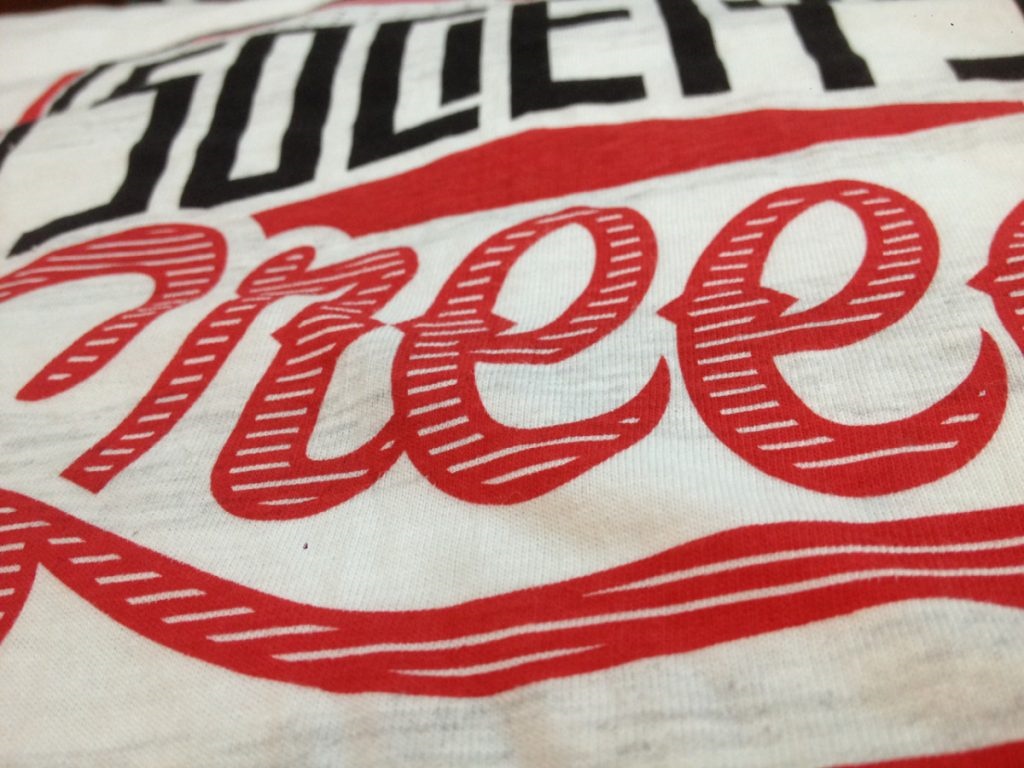

Printing Styles for Custom Bottoms

As you embark on customizing your custom bottoms to perfectly reflect your brand or design vision, our team is here to guide you through the printing process. We ensure that your personalized bottoms meet and exceed your expectations with a seamless, high-quality result.

Screen Printing

Screen printing is a traditional and widely-used printing technique, especially suitable for mass production of custom bottoms. It involves pressing ink through a special mesh screen onto the fabric, forming the desired pattern. Screen printing provides vibrant, long-lasting colors that resist fading or peeling.

- Application: Suitable for a wide range of bottoms, including joggers, casual pants, and leggings. Ideal for printing large logos or simple designs like brand logos or text.

Heat Transfer Printing

Heat transfer printing is a method that transfers printed designs onto the fabric using heat and pressure. This technique works well with all types of bottom fabrics and allows for high-definition, vibrant prints, capable of delivering detailed designs and gradients. Heat transfer printing is ideal for small batch customization, especially for leggings, yoga pants, and casual bottoms.

- Application: Perfect for bottoms requiring intricate patterns or multi-color designs, such as leggings, yoga pants, and joggers.

Sublimation Printing

Sublimation printing transfers dye into the fibers of polyester fabrics, becoming a permanent part of the fabric. The main advantage is that the design will not fade, crack, or peel, while maintaining the fabric’s original softness. Sublimation is ideal for custom bottoms made from polyester or synthetic materials, such as running pants or training trousers.

- Application: Suitable for durable, washable custom bottoms, including sports pants and yoga pants, especially for producing vibrant, complex designs.

Embroidery

Embroidery involves stitching colorful threads onto fabric to create designs or logos. It is typically used on thicker materials such as denim, corduroy, or wool blends. Embroidery adds a high-end texture and a three-dimensional feel to custom bottoms, enhancing durability and visual appeal.

- Application: Ideal for jeans, casual trousers, and even custom uniforms. Perfect for embroidered brand logos, patterns, or personalized text to enhance the quality and brand image of the garment.

Digital Printing

Digital printing uses inkjet technology to transfer images directly onto fabric. It allows for highly detailed and complex designs, making it suitable for small batch customization. Digital printing works well with all types of fabric and offers smooth color transitions without limitations on color or pattern complexity.

- Application: Suitable for fashionable pants, casual trousers, and innovative custom bottoms, particularly for personalized designs requiring intricate details.

Plastisol Printing

Plastisol printing uses thick inks to create vibrant colors and good opacity on dark fabrics. It results in a slightly raised texture that is durable and smooth to the touch.

- Application: Ideal for producing custom joggers, jeans, and casual trousers, commonly used when bright, durable designs are required.

Water-Based Printing

Water-based printing uses eco-friendly inks that penetrate the fabric, resulting in a soft, breathable finish. It works well on lightweight fabrics like cotton and linen and produces a more natural and soft look.

- Application: Best suited for summer trousers or loungewear, especially for relaxed, casual styles of bottoms.

Puff Printing

Puff printing is a special effect printing technique that uses heat to create a raised, three-dimensional texture in the printed design. This technique adds a tactile and visual uniqueness to custom bottoms, making it ideal for fashion-forward designs.

- Application: Suitable for trendy joggers, street-style pants, and custom bottoms that emphasize design elements.

Reflective Printing

Reflective printing uses special materials that reflect light, increasing visibility in low-light conditions. This technique is often applied to outdoor or night activity wear to enhance safety.

- Application: Ideal for night joggers, cycling pants, or outdoor adventure trousers, enhancing visibility and adding a unique design feature.

Glow-in-the-Dark Printing

Glow-in-the-dark printing uses special materials that emit light in the dark, adding a fun and unique effect to the design. This technique is popular in trendy clothing and enhances personalization.

- Application: Suitable for custom bottoms targeting a youthful, fashion-forward market, such as trendy joggers or streetwear pants.

Custom Bottoms Design Renderings

At JF Apparel, our expert team is dedicated to creating high-quality design renderings for your custom bottoms. Whether you’re looking for sleek, modern styles or unique, eye-catching patterns, we turn your concepts into professional designs that capture attention.

With meticulous attention to detail, we ensure that your ideas are translated into precise, visually stunning renderings that perfectly reflect your vision. Trust our expertise to elevate your custom bottoms with carefully crafted designs that leave a memorable impression.

Start with a Sample?

Have a design, logo, or an initial idea for your custom bottoms? Share your project specifics, such as fabric preferences, color options, and desired custom features. We’re here to assist in transforming your concept into reality with a carefully crafted sample. Our team will ensure that the sample aligns with your vision and meets your quality expectations, making the process seamless and straightforward.

Quality Assurance for Custom Bottoms

At JF Apparel, quality is embedded in every step of our production process. Our commitment goes beyond basic standards; we implement comprehensive quality control measures to ensure that each pair of custom bottoms meets your highest expectations.

From the careful selection of durable fabrics to precise stitching techniques, we scrutinize every aspect of production. Before leaving our facility, each garment undergoes a rigorous multi-point inspection, where we check for accuracy in measurements, fabric integrity, and overall craftsmanship. Only after passing these stringent checks do our custom bottoms earn the privilege of representing your brand.

Custom Bottoms Production Video

Explore how our custom bottoms are made, from the initial design phase to final production. Our video takes you through the entire process, highlighting key steps like fabric selection, cutting, stitching, and quality checks. You’ll see how each piece is carefully crafted to meet the highest standards, ensuring durability, comfort, and style. This video provides a clear, straightforward look at how our team turns raw materials into finished products.

Trusted by Leading Brands for Custom Bottoms

When you choose to produce your custom bottoms with us, you align with global brands that value our precision and reliability. Our long-standing partnerships with respected international brands reflect the trust placed in our manufacturing capabilities, ensuring that your custom bottoms are produced to the highest quality standards.

Streamlined Production Process for Custom Bottoms

At JF Apparel, we know that delivering top-quality custom bottoms starts with a well-structured and efficient production process. From the initial concept to the final product, we maintain complete control over every stage, ensuring each piece meets our strict quality standards.

Initial Consultation

Design and Sample Creation

Fabric Selection and Preparation

Fabric Cutting

Mass Production

Quality Assurance

Packaging and Labeling

Warehouse and Shipping

Frequently Asked Questions

Welcome to the FAQs on Branded Custom Bottoms in Bulk, where we address your common questions and provide valuable insights on styles, materials, and order-related details. Our goal is to help you make informed decisions that align with your brand’s needs and ensure your custom bottoms meet the highest standards for quality and design.

The best types of custom bottoms vary depending on style and occasion. Options range from comfortable joggers to tailored trousers, ensuring you can find the perfect fit for your brand.

Custom bottoms can be made from a variety of fabrics including cotton, polyester, spandex blends, and more, depending on the intended use and desired feel.

Consider the purpose, fabric, and style when choosing custom bottoms. Whether it’s for activewear, casual, or formal wear, selecting the right combination of materials and design is key.

The MOQ for custom bottoms typically ranges between 150 and 300 pieces, depending on the complexity of the design and fabric choice.

Yes, we can create a sample of your custom bottoms featuring your logo before full production.

Production lead time varies based on the complexity of the order, but typically ranges from 15 to 30 days after sample approval.

Shipping times depend on the destination, with most deliveries taking between 7 to 15 days once production is complete.

Yes, we offer a full range of sizes from XS to XXL, or you can provide your own sizing chart for a more tailored fit.

Custom Bottoms with Your Logo - Personalized Bottoms for Your Brand Promotions

Looking for a fresh and practical way to elevate your brand? Our custom bottoms with your logo provide an ideal solution for businesses, events, and organizations seeking to leave a lasting impression with high-quality, functional apparel.

Picture your brand’s logo showcased on comfortable, stylish custom bottoms—designed to suit a variety of occasions. Whether it’s for your team, clients, or event attendees, these personalized bottoms offer a unique combination of style and practicality.

We offer a wide range of customization options, from fabrics and cuts to colors and design features, ensuring that your brand is represented just the way you want. Whether you’re opting for joggers, tailored trousers, or performance leggings, our custom bottoms are designed to make your brand stand out with elegance and precision.

Our process is more than just adding a logo—it’s about creating something that truly reflects your brand’s identity. With a selection of printing techniques, colors, and details, you can craft a product that resonates with your audience. Our team is ready to assist in bringing your vision to life, ensuring the finished product is exactly as you imagined.

Not only do our custom bottoms enhance your brand, but they also offer functional features for everyday wear. Made with durable materials and thoughtful design details such as reinforced stitching, elastic waistbands, and practical pockets, they provide long-lasting comfort and utility.

Make your next marketing move impactful with custom bottoms that speak to your brand’s values. Whether you’re preparing for a corporate event or seeking to enhance your brand’s reach, our personalized bottoms are the ideal solution.

Interested in taking the next step? Reach out today to explore our custom bottom options and start creating your own branded apparel.