When I first started diving into the apparel supply chain, I was constantly debating: “Should I go with American factories or Chinese ones?” To be honest, it’s not an easy decision to make.

Over time, I realized that it’s not just me—many of my peers struggle with the same question. So, I did some deep research, combined it with my experience working with different brand clients, and now I’m here to break it down for you.

So, which is the better option for your brand—American or Chinese factories? The answer boils down to your specific needs. Both American and Chinese clothing factories have their own strengths and weaknesses. Choosing an American factory could mean faster turnaround times and stricter quality control, but at a higher production cost. On the other hand, Chinese factories often provide lower manufacturing costs and more diverse production capabilities but can have longer delivery times and shipping challenges.

If you’re in a rush to decide, the summary above should give you some clarity. However, if you want to dig deeper, keep reading—I’ll break down the pros and cons from a few key perspectives.

Advantages of American Clothing Factories

1. Faster Turnaround to Meet “I Need It Now” Demands

One of the biggest concerns for many brands is delivery speed. American factories usually deliver within 4-8 weeks, which is about 40%-50% faster than the shipping time from China. For brands looking to “launch new collections immediately and seize market trends,” this speed can make all the difference. Take fast-fashion brand Reformation as an example: their local production allows them to go from design to shelf in just 3-4 weeks, keeping up with the fast-paced market.

2. Strict Quality Control to Avoid “Defective Product” Complaints

For many brands, quality control is a top priority. You definitely don’t want to find flaws in your product once it reaches the customer, right? American factories tend to have higher quality standards, with return rates averaging below 2%, while similar factories in China usually range between 3%-5%. Brands like Everlane choose American factories to ensure every detail meets their high standards, reducing the risk of customer complaints and product returns.

3. Strong Social Responsibility, Enhancing Brand Image

Today’s consumers care more about ethical production, which means your choice of factory can significantly impact your brand image. American factories adhere to strict labor rights and environmental standards, which can help brands feel more confident in their supply chain. Take Patagonia, for instance. A brand focused on sustainability and ethical practices, they emphasize their brand values by working with American factories, ensuring customers appreciate not just the product quality but also the brand’s commitment to sustainability.

Disadvantages of American Clothing Factories

1. Higher Production Costs—Impacting Profit Margins

One major downside of American factories is the higher production cost, which is usually 20%-40% more than in China. For example, producing a basic T-shirt in the U.S. might cost around $15-$20, while the same quality T-shirt in China would cost about $7-$10. If you’re cost-conscious or want to maintain competitive pricing, the high manufacturing expenses in the U.S. might affect your profit margins.

2. Limited Production Capacity—Challenges with Scaling Up

Many brands worry about production capacity. American factories are typically smaller, with an average monthly output of 5,000-10,000 pieces. If your product suddenly becomes a hit and you need to scale up quickly, one American factory might not be able to handle it all. Outdoor Voices faced this challenge—they eventually had to split their orders across multiple factories, which complicated logistics and increased costs.

3. High Costs for Special Fabrics and Techniques

If your product requires unique craftsmanship or specialty materials like lace, embroidery, or digital printing, American factories have limited options and higher costs in these areas. This can be a concern for brands seeking unique designs but working with a limited budget.

Advantages of Chinese Clothing Factories

1. Lower Costs—More Profits for Your Brand

Without a doubt, cost-effectiveness is the biggest advantage of Chinese factories. On average, production costs in China are 30%-50% lower than in the U.S. I helped lingerie brand ThirdLove analyze their production expenses, and by moving manufacturing to China, they reduced their cost per item by about 40%. Such savings can significantly boost your brand’s profit margins.

2. High Production Capacity—Flexibility for Any Order Size

Flexible production capacity is another major benefit of Chinese factories. Whether you need 100 pieces or 100,000, Chinese factories can adapt quickly. Fast-fashion giant Fashion Nova relies on Chinese factories to produce up to 100,000 items monthly while quickly updating product designs to keep up with market trends.

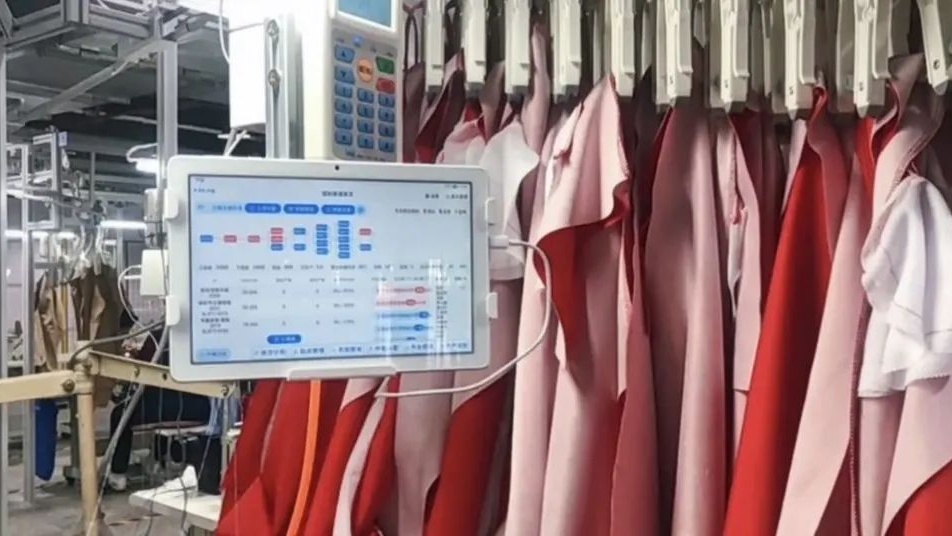

3. Diverse Techniques & Manufacturing Capabilities

Chinese factories have a wide range of manufacturing capabilities, covering various fabrics and techniques—knitwear, silk, embroidery, printing, and even digital dyeing. I once helped a luxury swimwear brand find a factory in Guangzhou that not only met their requirements for quick-drying fabrics but also complied with environmental standards. It’s this kind of versatility that makes Chinese factories suitable for various brand needs.

Disadvantages of Chinese Clothing Factories

1. Longer Delivery Times—Risk of Missing Market Opportunities

The lead time for Chinese factories is longer—typically around 8-12 weeks, with 30-40 days just for shipping. For brands looking to quickly bring products to market or cater to seasonal demand, this longer timeline can pose challenges. I worked with an independent designer brand that chose American factories primarily to cut down on delivery time for their new product launch.

2. Inconsistent Quality—Choosing the Right Supplier is Key

While there are plenty of Chinese factories, quality varies greatly. Some smaller factories may struggle to deliver consistent quality or keep up with deadlines. Finding the right supplier can be a significant challenge for brands. I once helped a denim brand find a reliable supplier in China, and it took several rounds of vetting to find a factory that met their standards.

3. Variable Social Responsibility Standards

Many brands worry about how working with Chinese factories may affect their social image. Although most Chinese factories are improving their labor rights and environmental standards, some are still behind. If your brand places a strong emphasis on ethical production and social responsibility, you’ll need to thoroughly audit any factory you partner with in China.

My Recommendation: How to Balance Brand Needs with Factory Selection

Before you decide, ask yourself: What are my brand’s priorities? If your brand needs fast delivery, high-quality control, and has the budget to support it, then an American factory may be your best bet. On the other hand, if you’re looking for cost savings, large-scale production, and a variety of fabric and technique options, then a Chinese factory might be the better fit.

Regardless of which country you choose, my advice is: Maintain close communication with your factory, regularly check production progress and quality, and build a long-term partnership. This not only ensures a stable supply chain but also helps you continuously optimize and enhance product quality.

If you’re interested in learning more about finding the right factories for your brand, be sure to check out my other articles: 【How to Quickly Find Quality Factories in China】 and 【How to Quickly Find Quality Factories in the U.S.】